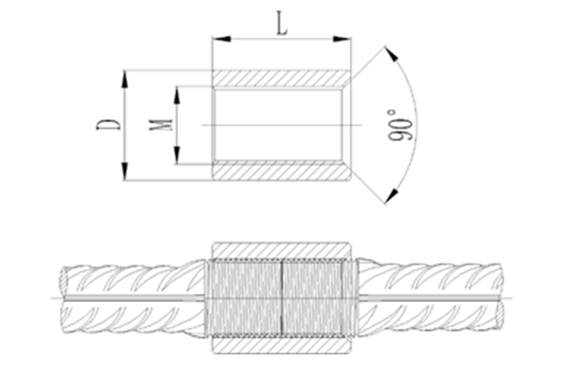

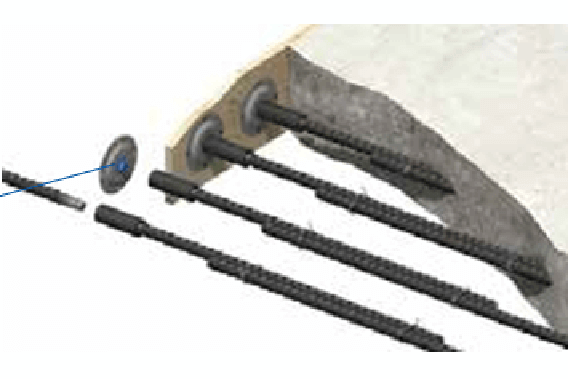

Used for precisely installing coupler to formwork.

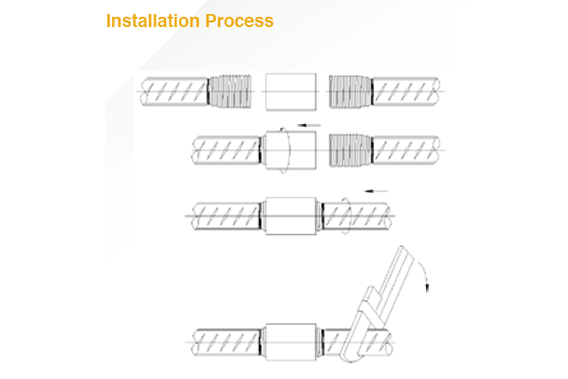

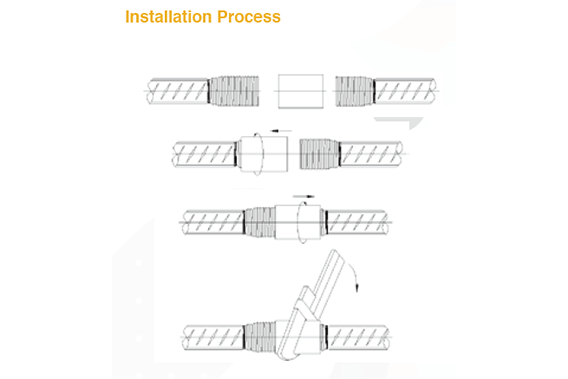

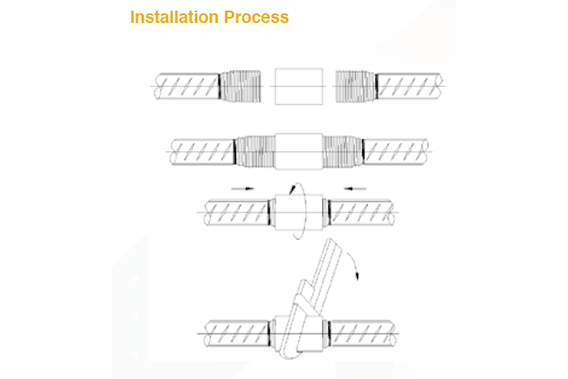

Installation Process – Wooden Formwork

1. Make holes on the formwork to match nail plate installing holes

2. Fix nail plate by nails to the formwork

3. Connect coupler (one side is connected with rebar) to nail plate to the correct position

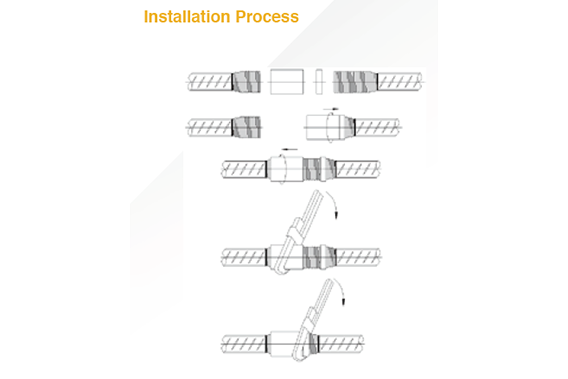

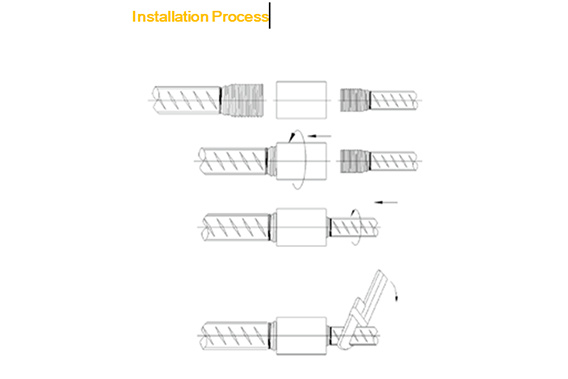

Installation Process – Steel Formwork

1. Assemble magnets, cover and nail plate together

2. Mark position on the steel formwork

3. Fix nail plate by magnets to the formwork

4. Connect coupler (one side is connected with rebar) to nail plate to the correct position

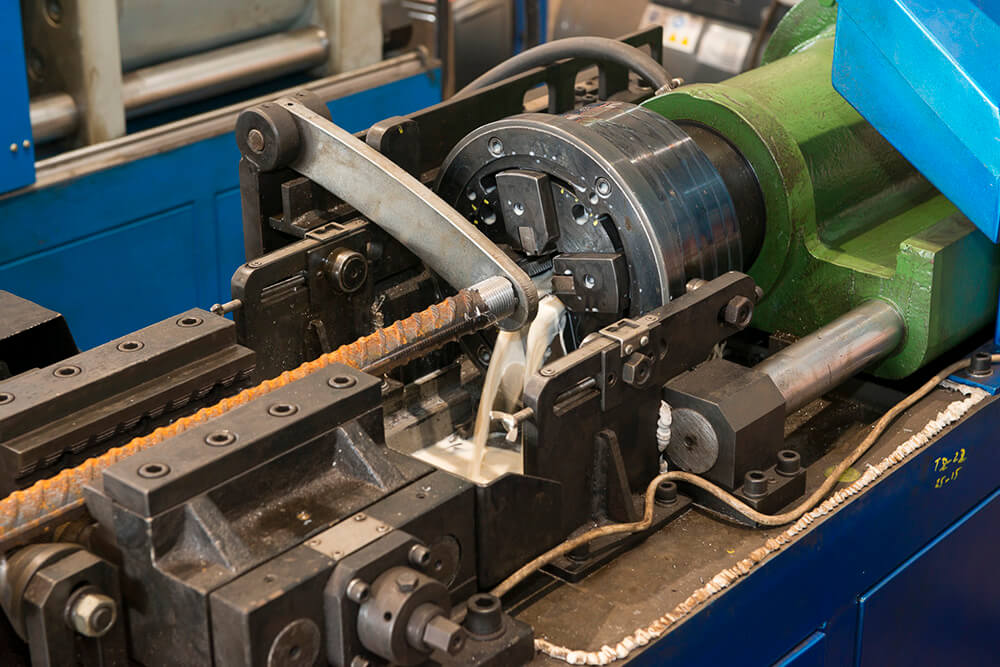

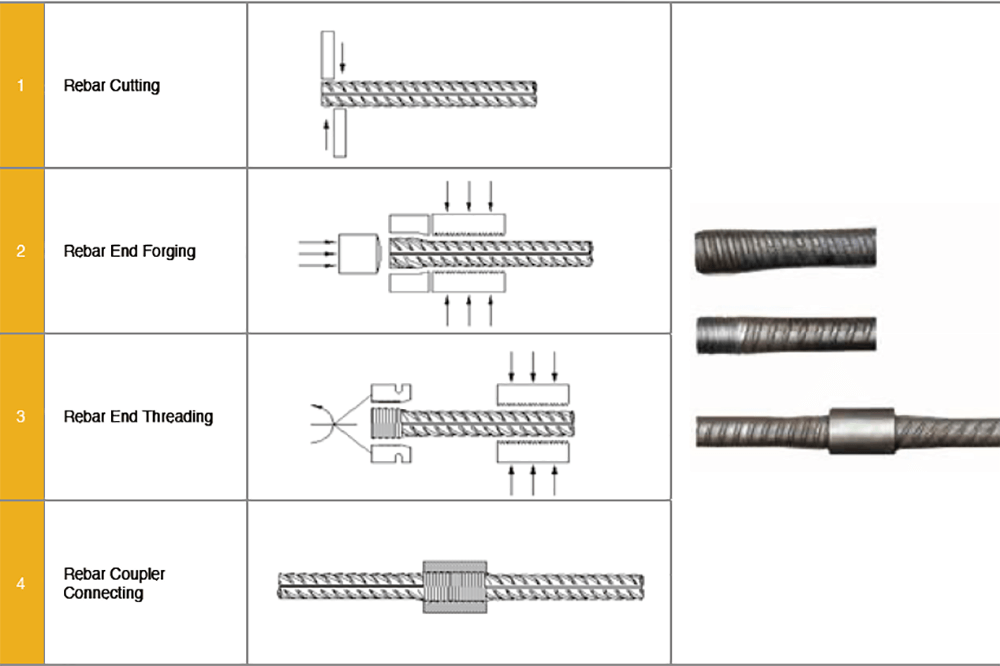

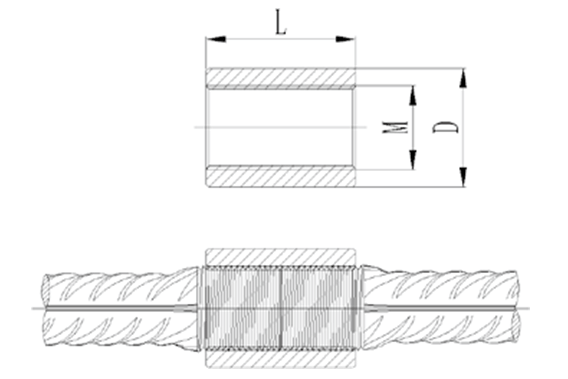

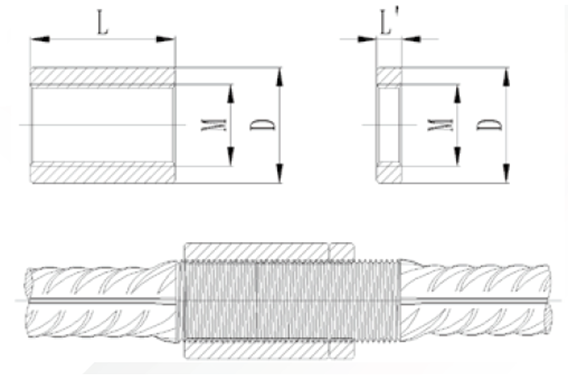

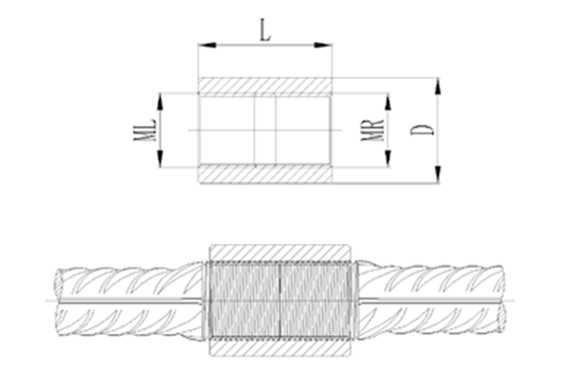

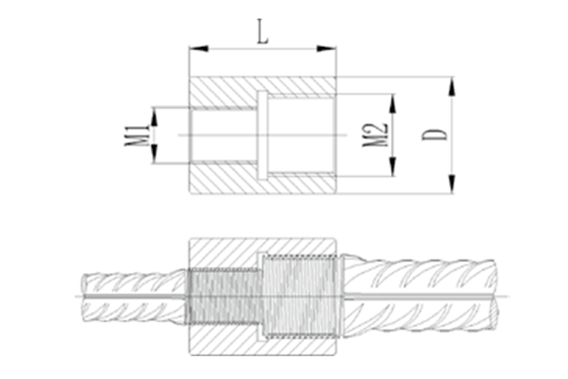

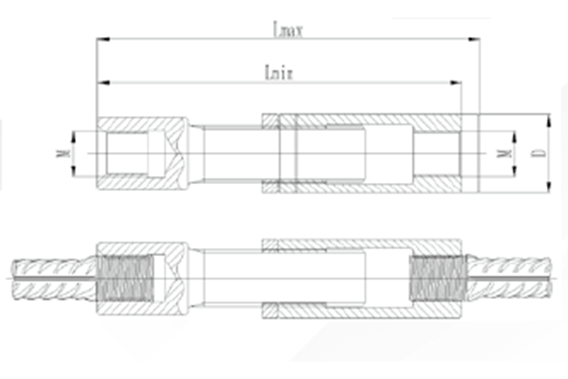

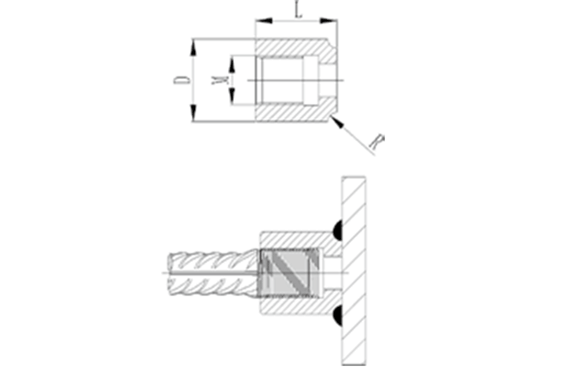

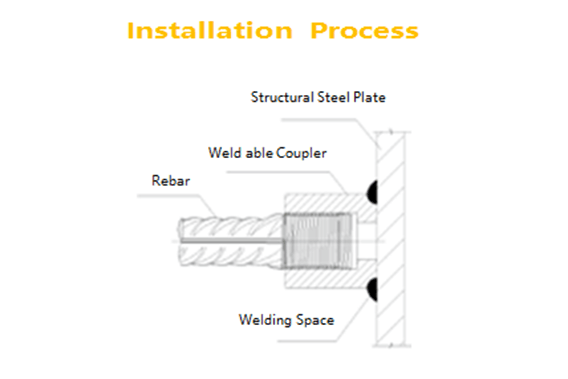

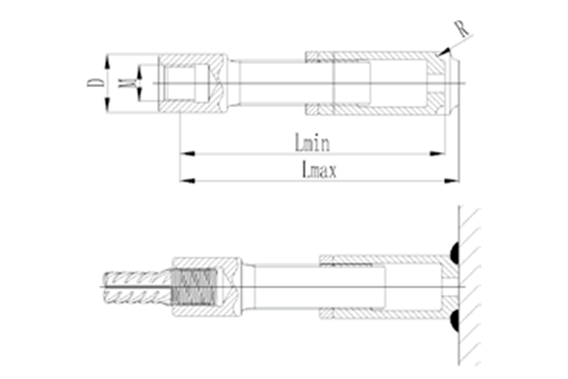

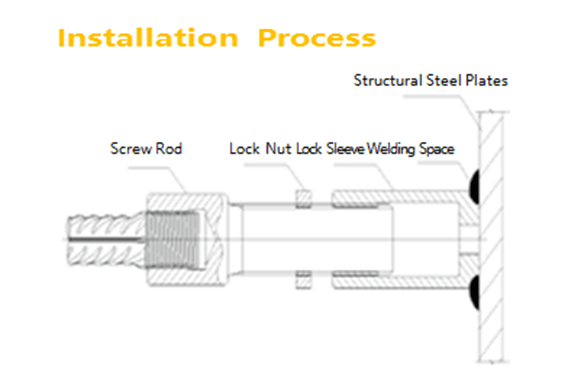

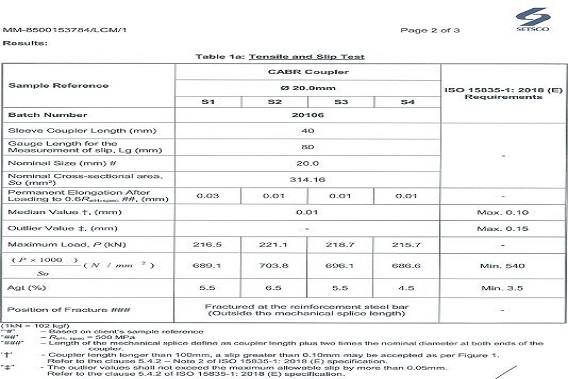

Coupler Specification – suitable for 500MPa Rebar